Suitable for cleaning semiconductors, optical concave convex mirrors, and flat glass;

Equipped with a workpiece up and down shaking system, the cleaning system has a uniform effect;

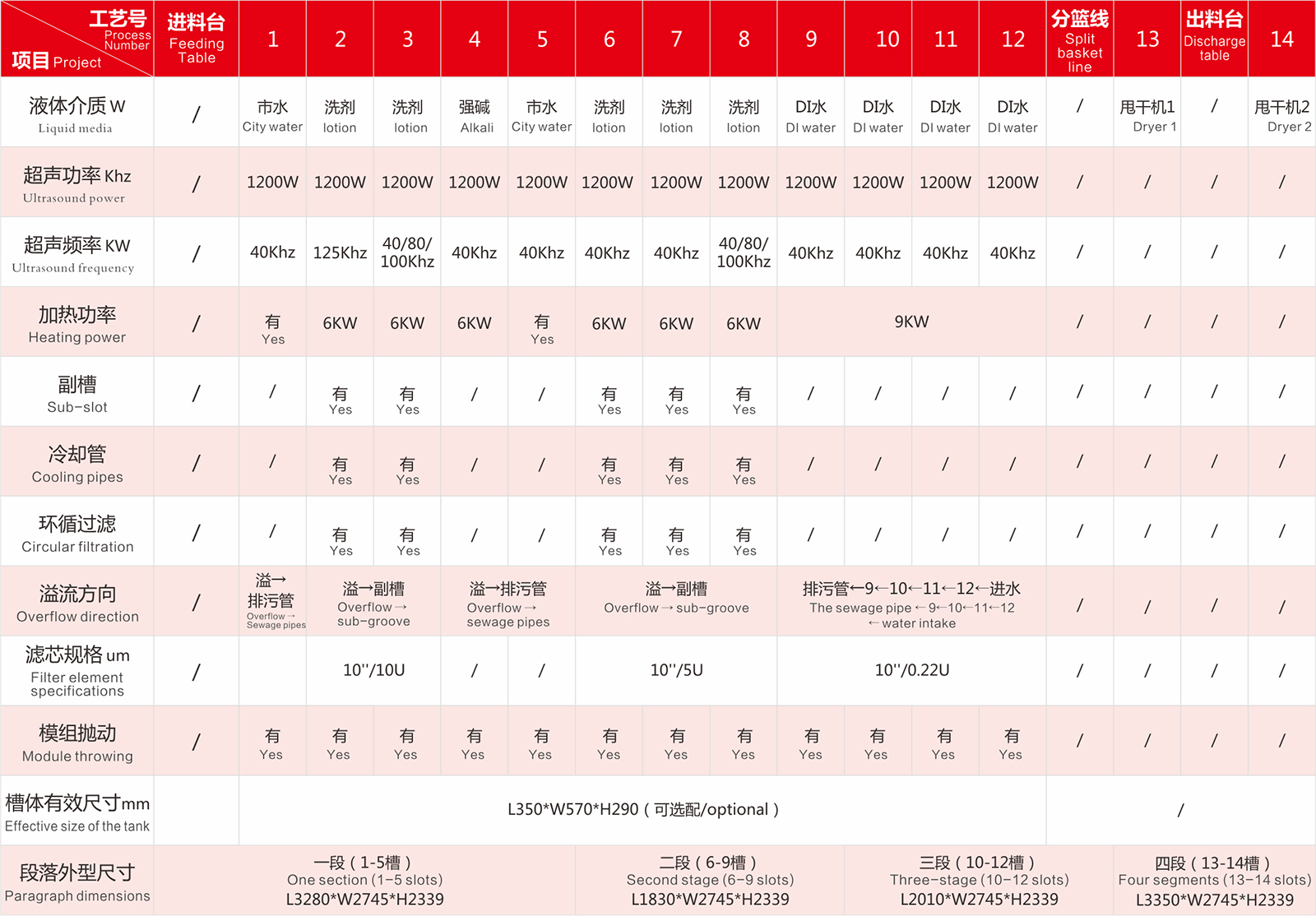

◆ Using high-frequency ultrasonic frequencies such as 40KHz, 80KHz, 100KHz, 125KHz, etc;

◆ Ultrasound uses a generator with an efficiency of up to 95%, and the power is adjustable from 10% to 100%;

◆ The design of throwing, lateral movement, and transmission mechanisms should be gentle and low in vibration;

The cleaning process function program can be freely changed;

The drying machine system is designed with manual function

◆ The surface of the ultrasonic vibration plate is treated with hard chromium plating, effectively resisting acid and alkali corrosion;

◆ The cleaning tank is uniformly equipped with saw shaped overflow ports and shallow V-shaped grooves on all sides for overflow;

Design a graduated flow meter at the main water inlet;

◆ QR code scanning, recognition, and cleaning technology, with controllable time setting and entry function

◆ The computer stores cleaning data for each product frame, allowing for traceability of issues;

All inlet and circulating stainless steel pipes are connected with snap fasteners;

All doors and windows are equipped with anti opening protection devices;

◆ The robotic arm grabs the product frame and automatically enters the drying machine;

The tank body is made of stainless steel material SUS304/316, which is optional.